Offset printing, also called lithography, is the most common kind of printing for high-volume commercial jobs. Colortech provides PMS (Pantone Matching System) and 4-color offset printing that is widely used to print projects such as booklets, brochures, and newsletters.

Overall, offset printing offers high-quality, cost-effective, and versatile printing solutions, making it a preferred choice for various applications, including brochures, catalogs, magazines, packaging, stationery, and marketing collateral.

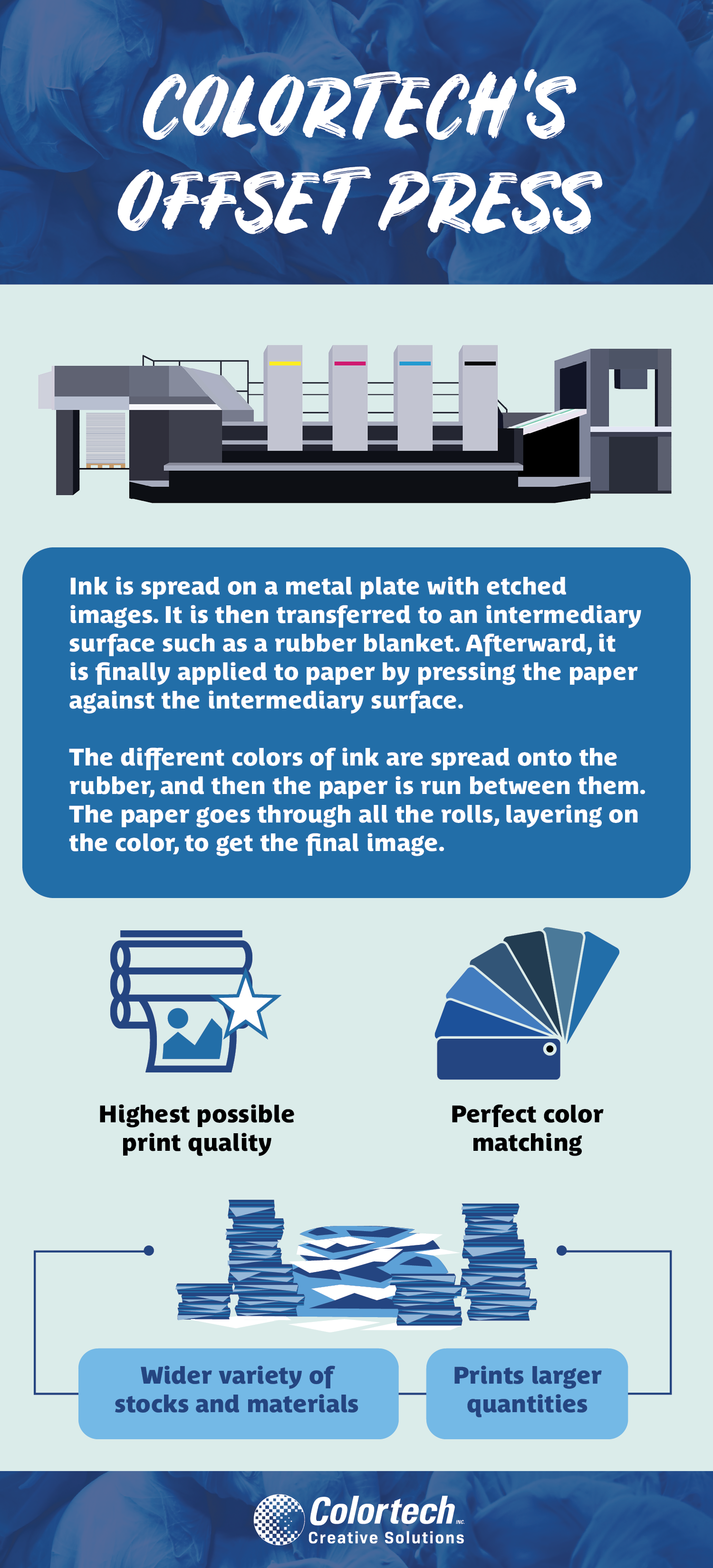

Here’s how it works: ink is spread on a metal plate with etched images. It is then transferred to an intermediary surface such as a rubber blanket. Afterward, it is finally applied to paper by pressing the paper against the intermediary surface.

The different colors of ink are spread onto the rubber, and then the paper is run between them. The paper goes through all the rolls, layering on the color, to get the final image.

Offset printing is called as such since the ink is not transferred directly onto the paper. This process takes a bit longer than digital printing since the paper product needs to dry before finishing.

Benefits to Using an Offset Printing Press

- High-Quality Printing: Offset printing provides excellent print quality and precision. It can reproduce fine details, sharp images, and vibrant colors, resulting in professional-looking printed materials.

- Cost-Effective for Large Volumes: Offset printing is highly efficient and cost-effective for large print runs. Once the printing plates are set up, the cost per unit decreases significantly, making it an economical choice for high-volume printing projects.

- Wide Range of Substrates: Offset printing can be used on a wide range of substrates, including paper, cardstock, fabric, metal, plastic, and more. It allows for printing on different textures, thicknesses, and finishes, providing versatility and flexibility for various printing needs.

- Consistency and Color Accuracy: Offset printing utilizes the Pantone Matching System (PMS) or CMYK color model, ensuring consistent and accurate color reproduction. This is particularly important for branding materials, where color consistency across different printed pieces is essential.

- Wide Color Gamut: Offset printing can achieve a wide color gamut, allowing for a broad spectrum of vibrant and nuanced colors. It is particularly beneficial for projects that require precise color matching or vibrant and eye-catching designs.

- Large Printing Format: Offset printing can handle larger printing formats, accommodating larger paper sizes and printing dimensions. This is advantageous for projects such as posters, banners, signage, and other large-scale promotional materials.

- Ability to Print Special Inks and Finishes: Offset printing supports the use of various specialty inks, such as metallic, fluorescent, and spot colors. It also enables the application of finishes like varnishes, coatings, embossing, and foiling, enhancing the visual appeal and tactile experience of the printed materials.

- Quick Production Time: Once the initial setup is complete, offset printing allows for high-speed production, making it suitable for tight deadlines and time-sensitive projects.

- Long-lasting and Durable Prints: Offset printing produces prints that are highly resistant to fading and wear. The inks used in offset printing are more durable compared to other printing methods, ensuring longevity and preserving the quality of the printed materials over time.